-

Rockwool tấm Sandwich

-

Tấm Sandwich bông thủy tinh

-

Tấm Polyurethane Sandwich

-

Bảng điều khiển bánh sandwich âm thanh

-

Kho thép tiền chế

-

Tấm ốp kim loại

-

tấm kim loại đục lỗ

-

Thép tấm định hình

-

Ván sàn thép

-

Bảng nhôm Sandwich

-

Nhà chứa có thể gập lại

-

Bảng điều khiển bánh sandwich EPS

-

Bảng điều khiển bánh sandwich trang trí

-

Góc bảng điều khiển bánh sandwich

-

Vòng cuộn tấm thép

-

Bông thủy tinh cách nhiệt

-

Bảo hiểm bằng vải đá

-

Dầm kết cấu thép

-

góc thép

-

Phần kênh thép

-

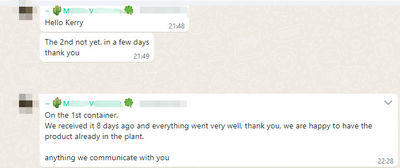

ÔNG"Chúng tôi đã nhận được nó 8 ngày trước và mọi thứ diễn ra rất tốt, cảm ơn bạn, chúng tôi rất vui khi nhận đượcsản phẩm đã có trong nhà máy.Bất cứ điều gì chúng tôi liên lạc với bạn"

ÔNG"Chúng tôi đã nhận được nó 8 ngày trước và mọi thứ diễn ra rất tốt, cảm ơn bạn, chúng tôi rất vui khi nhận đượcsản phẩm đã có trong nhà máy.Bất cứ điều gì chúng tôi liên lạc với bạn" -

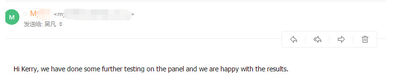

ÔNG"Xin chào Kerry, chúng tôi đã thực hiện thêm một số thử nghiệm trên bảng điều khiển và chúng tôi hài lòng với kết quả."

ÔNG"Xin chào Kerry, chúng tôi đã thực hiện thêm một số thử nghiệm trên bảng điều khiển và chúng tôi hài lòng với kết quả." -

Bàrất hài lòng và sản phẩm tốt. Vận chuyển nhanh chóng và mọi thứ diễn ra rất tốt.

Bàrất hài lòng và sản phẩm tốt. Vận chuyển nhanh chóng và mọi thứ diễn ra rất tốt.

Prefabricated Buildings Steel Structure Warehouse Metal Building Prefab Workshop Steel Building Construction

| Nguồn gốc | Hà Lan, Trung Quốc |

|---|---|

| Hàng hiệu | BAODU |

| Chứng nhận | ISO9001,CE |

| Số mô hình | Kho thép |

| Tài liệu | Sổ tay sản phẩm PDF |

| Số lượng đặt hàng tối thiểu | 1000mét vuông |

| Giá bán | $25-45square meter |

| chi tiết đóng gói | Nói chung, đối với cấu trúc thép, chúng tôi sử dụng đóng gói khung thép để giữ cho hàng hóa không bị |

| Thời gian giao hàng | 45 ngày |

| Điều khoản thanh toán | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Khả năng cung cấp | 5000 mét vuông/mét vuông mỗi ngày |

Liên hệ với tôi để lấy mẫu miễn phí và phiếu giảm giá.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Ứng dụng trò chuyện: sales10@aixton.com

Nếu bạn có bất kỳ mối quan tâm nào, chúng tôi cung cấp trợ giúp trực tuyến 24 giờ.

x| Tên sản phẩm | Nhà tiền chế Kết cấu thép Nhà kho Nhà kim loại Xưởng tiền chế Xây dựng nhà thép | Từ khóa | Kho hàng hóa bằng thép |

|---|---|---|---|

| Tấm ốp tường | EPS/Rockwool/Fiberlass Wool/PU Sandwich bảng điều khiển hoặc tấm thép | Dịch vụ xử lý | Uốn cong, hàn, khử trùng, cắt, đấm |

| Ứng dụng | Kho thép, nhà máy hoặc kho hậu cần | Ốp mái | EPS/Rockwool/Fiberlass Wool/PU Sandwich bảng điều khiển hoặc tấm thép |

| Thiết kế bản vẽ | Sap2000/Autocad /Pkpm /3D3s/Tekla | Hiệu suất | Bảo vệ thính giác an toàn, chống nước, cách âm, v.v. |

| Bảo hành | Hơn 50 năm | Khung chính | Dầm thép hình chữ H rắn |

| Làm nổi bật | prefabricated steel warehouse building,metal workshop prefab construction,steel structure warehouse with warranty |

||

As a professional supplier of steel structure workshops, we deliver high-quality, cost-effective building solutions tailored to industrial production, warehousing, logistics, and manufacturing needs worldwide. Our steel structure workshops stand out for their exceptional performance, flexibility, and sustainability--ideal for businesses seeking reliable and future-ready facilities.

- Superior Structural Safety & Durability

- Constructed with high-grade Q235/Q355 steel materials, our workshops boast excellent load-bearing capacity, corrosion resistance, and seismic performance (complying with international standards like AISC, Eurocode 3, or GB)

- Anti-rust treatment (galvanization/painting) and weather-resistant design ensure a service life of 50+ years, reducing maintenance costs significantly

- Wind load resistance (up to 0.75kN/m²) and snow load capacity (customizable per region) guarantee stability in extreme conditions

- Flexible Design & Customization

- Fully customizable dimensions (span: 10-50m, length: unlimited, eave height: 4-12m) to fit your production workflow and equipment layout

- Modular prefabricated components enable easy expansion, renovation, or relocation as your business grows

- Optional configurations: crane systems (1-50t), mezzanine floors, insulation layers, ventilation systems, and fireproof coatings

- Efficient Construction & Cost Savings

- Prefabricated production in our factory reduces on-site construction time by 30-50% compared to traditional concrete buildings

- Lightweight structure lowers foundation costs and transportation expenses

- High recyclability of steel materials aligns with environmental standards and reduces carbon footprint

- Wide Application Scope

- Industrial workshops, manufacturing plants, warehouses, logistics centers, aircraft hangars, exhibition halls, and agricultural sheds

- Suitable for various climates (tropical, temperate, cold regions) with adaptive design adjustments

All steel components undergo strict quality inspections (ultrasonic testing, dimensional checks) and are certified by ISO 9001, CE, or other international certifications.

Professional engineering team provides one-stop services: design, production, delivery, installation guidance, and after-sales support.

| Name | Steel Structure Building |

|---|---|

| Main Material | Q235 - Q420 Welded H Beam And Hot Rolled Section Steel |

| Surface | Painting Or Galvanizing |

| Roof And Wall Panel | EPS Sandwich Board, Single Corrugated Steel Plate, Glass Cotton Colored Board for Customers'Choice |

| Window | PVC Or Aluminum Alloy |

| Door | Sliding Door Or Rolling Shutter Door |

| Service |

Design: We have experienced designers to design. Manufacture: We can manufacture all kinds of steel structure products according to customers'needs. Installation: We provide detailed drawings to ensure installation.It also provides installation,supervision and training services. We can also send a team of engineers to guide or install on site. |

| Packing |

|

| Quality Inspection | Factory Self-inspection, Customer Inspection, Third Party Inspection |

We have a professional design team about 40 people, with 10 years design experience. We can meet your individual needs. And multi-type steel components, roof and wall panels, doors and windows for choosing.

| Location (where will be built) | _____country, area |

|---|---|

| Size: length*width*height | _____mm*_____mm*_____mm |

| wind load (max. wind speed in 50 years) | _____kn/m2, _____km/h, _____m/s |

| snow load (max. snow height) | _____kn/m2, _____mm |

| anti-earthquake | _____level |

| brickwall needed or not | If yes, 1m or 1.2m high or 1.5m high |

| thermal insulation | If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; if not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former. |

| mezzanine | If with mezzanine, what's the size and height? |

| door quantity & size | _____units, _____(width)mm*_____(height)mm |

| window quanity & size | _____units, _____(width)mm*_____(height)mm |

| crane needed or not | If yes, _____units, max. lifting weight____tons; max. lifting height _____m |

| Roof skylight panel | PC/ PVC/ FRP |

| Ventilator | unpower/ power ventilator |

- Superior Strength & Durability

- Made from high-grade steel (Q235, Q355, or ASTM A572), our structures offer exceptional load-bearing capacity, resistance to extreme weather, and long-term performance

- Corrosion-resistant coatings (hot-dip galvanizing, painted, or powder-coated) protect against rust and degradation, even in harsh environments

- Customizable & Modular Designs

- We provide bespoke solutions tailored to your needs--from clear-span widths, height, and roof styles to door/window placements and insulation options

- Pre-engineered components ensure fast, error-free assembly, reducing labor costs and construction time

- Cost-Effective & Eco-Friendly

- Steel is 100% recyclable, making our structures a sustainable choice

- Lightweight yet strong components minimize foundation requirements and shipping costs

- Wide Applications

- Warehouses & Logistics Centers: Large, column-free spaces for maximum storage

- Industrial Buildings: Factories, workshops, and manufacturing plants

- Commercial Spaces: Supermarkets, showrooms, and offices

- Agricultural Buildings: Barns, grain storage, and poultry farms

- Special Structures: Hangars, stadiums, and multi-story buildings

- Certification & Quality Assurance

- Our products comply with ISO 9001, CE, and other global certifications

- Strict quality control from material sourcing to production and packaging

The characteristics of your sandwich panels respectively:

1.EPS(polystyrene)sandwich panel: thickness is 50mm, 75mm, 100mm. The EPS volume weight is 8-20Kg/m3, water-proof.

2.Rock wool sandwich panel: thickness is 50mm, 75mm, 100mm. Rock wool volume weight is 80-120Kg /m3, fire-proof, sound-insulation, heat-preservation.

3.Glass wool sandwich panel: thickness is 50mm, 75mm, 100mm. Glass wool volume weight is 30-60Kg /m3, fire-proof, sound-insulation, heat-preservation.

4.PU(polyurethane)sandwich panel: thickness is 50mm, 75mm, 100mm. PU volume weight is 40-80/m3 water-proof, fire-proof, heat-proof, heat-insulation, heat-preservation, sound-insulation.